Underground tunnel custom engineered

emergency lighting fittings

for Transport application

Background - 15km underground rail network

Metro operates 210 six carriage trains across 869 kilometres of track throughout Melbourne.

During a review of a 15km underground rail network that connects four stations in the Melbourne CBD, it was agreed that the emergency lighting technology installed along these tunnel networks were out of date, triggering a need to look at more current technologies in relation to testing capability, lighting performance, maintenance and safety in the event of an evacuation being required.

Metro worked alongside ARUP engineers to specify the required performance and placed the tender into the market for manufacturers to present solutions.

The Challenge - Custom fittings had to be designed, manufactured, installed and commissioned

The challenge to meeting the specification was ensuring that the following conditions were met:

- Emergency lighting was required to achieve a minimum duration of 4 hours in emergency mode

- The maintained light output needed a significant improvement compared to the existing lighting and therefore a likelihood that additional wiring and fittings would be required

- The existing infrastructure with respect to the automatic testing was old telephone cable and this posed some risk with respect to providing a robust enough backbone communications for a new system.

- Every component installed within the tunnels had to be approved as Low-Smoke-Zero-Halogen

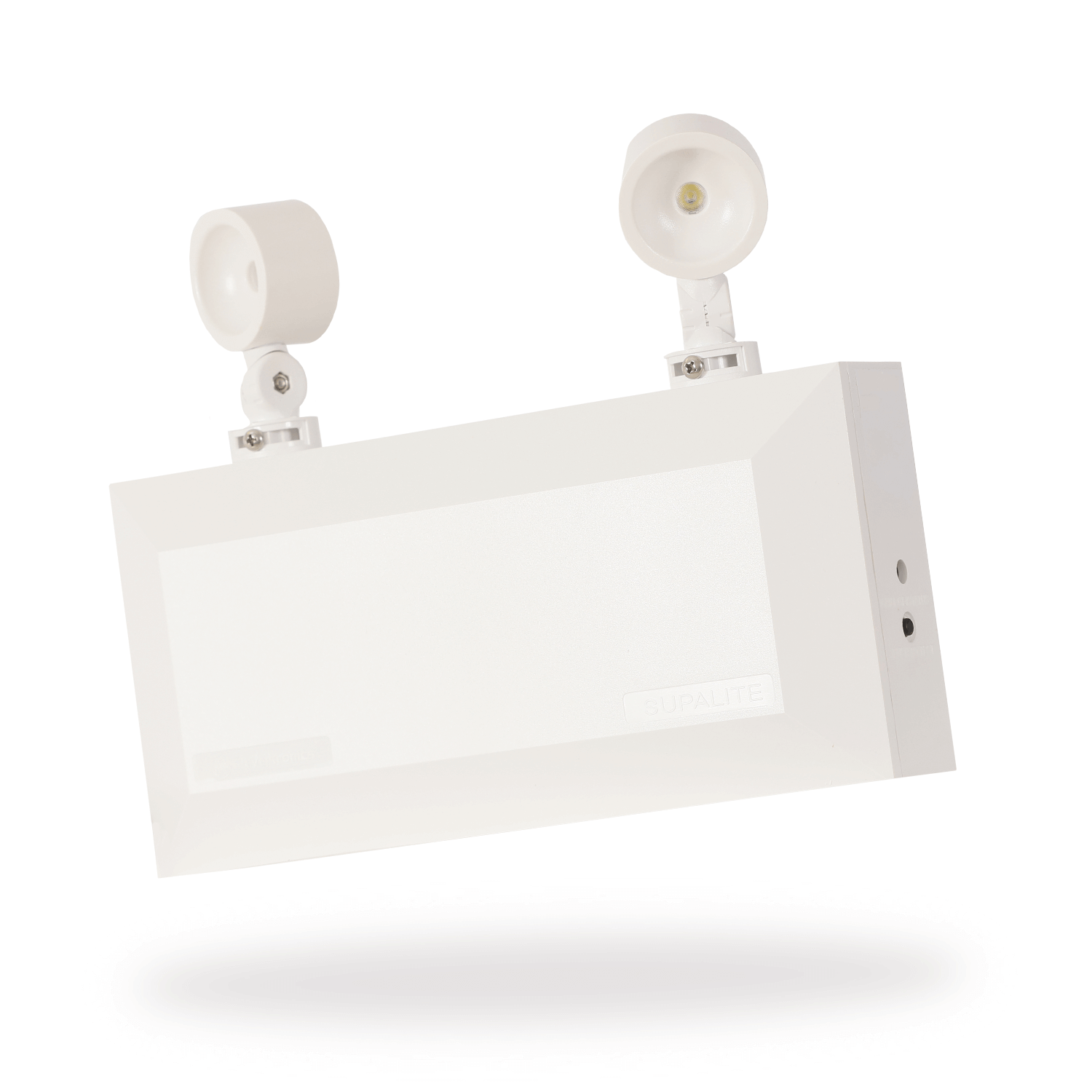

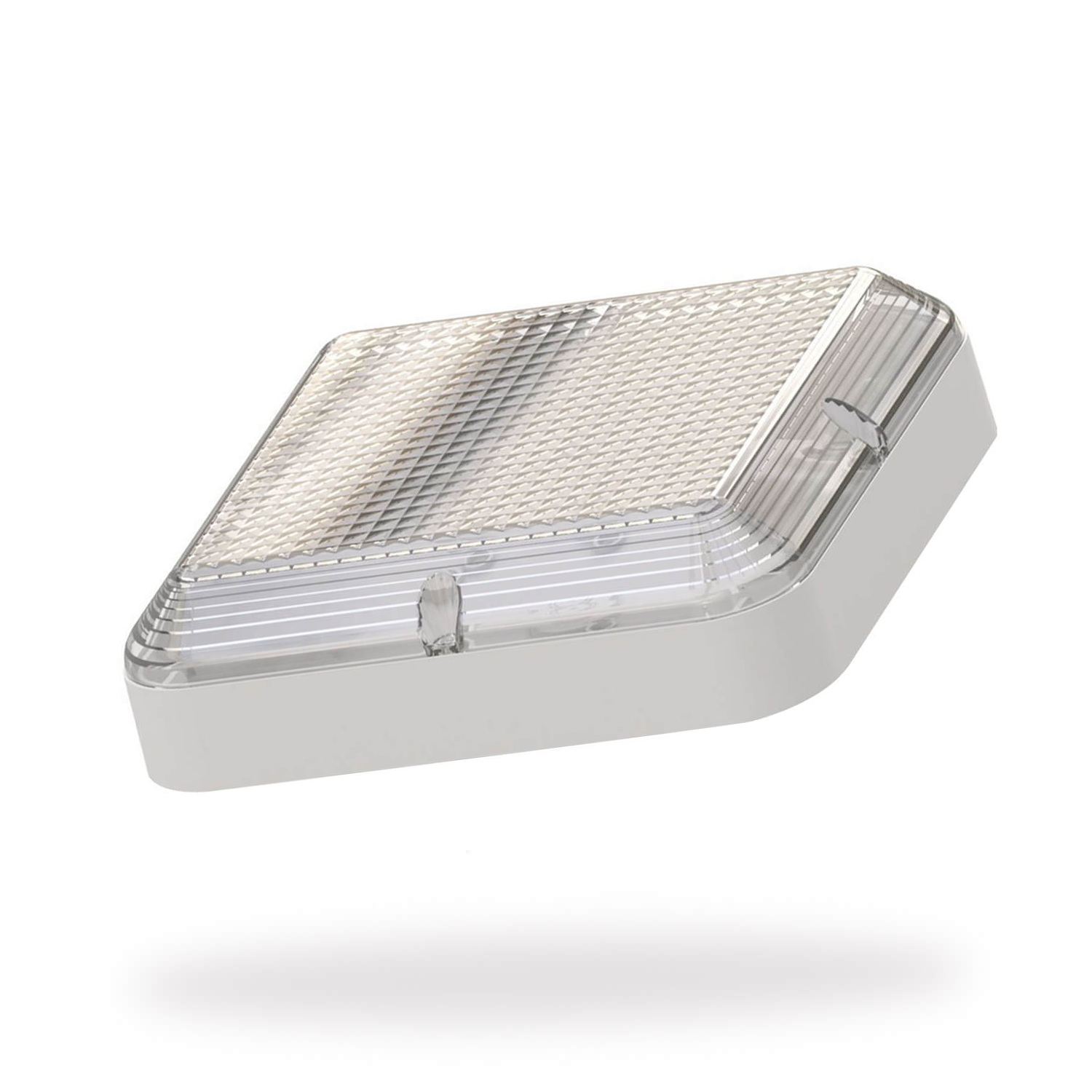

- The curved nature of the tunnel walls meant that the lighting had to be fixed at varying angles in order to disperse the correct light level to the ground surface 1,800 custom fittings had to be designed, manufactured, installed and commissioned in less than 12 months to meet Metro Trains’ project management timeline.

The Solution - Custom comprehensive solution to meet all of the specifications

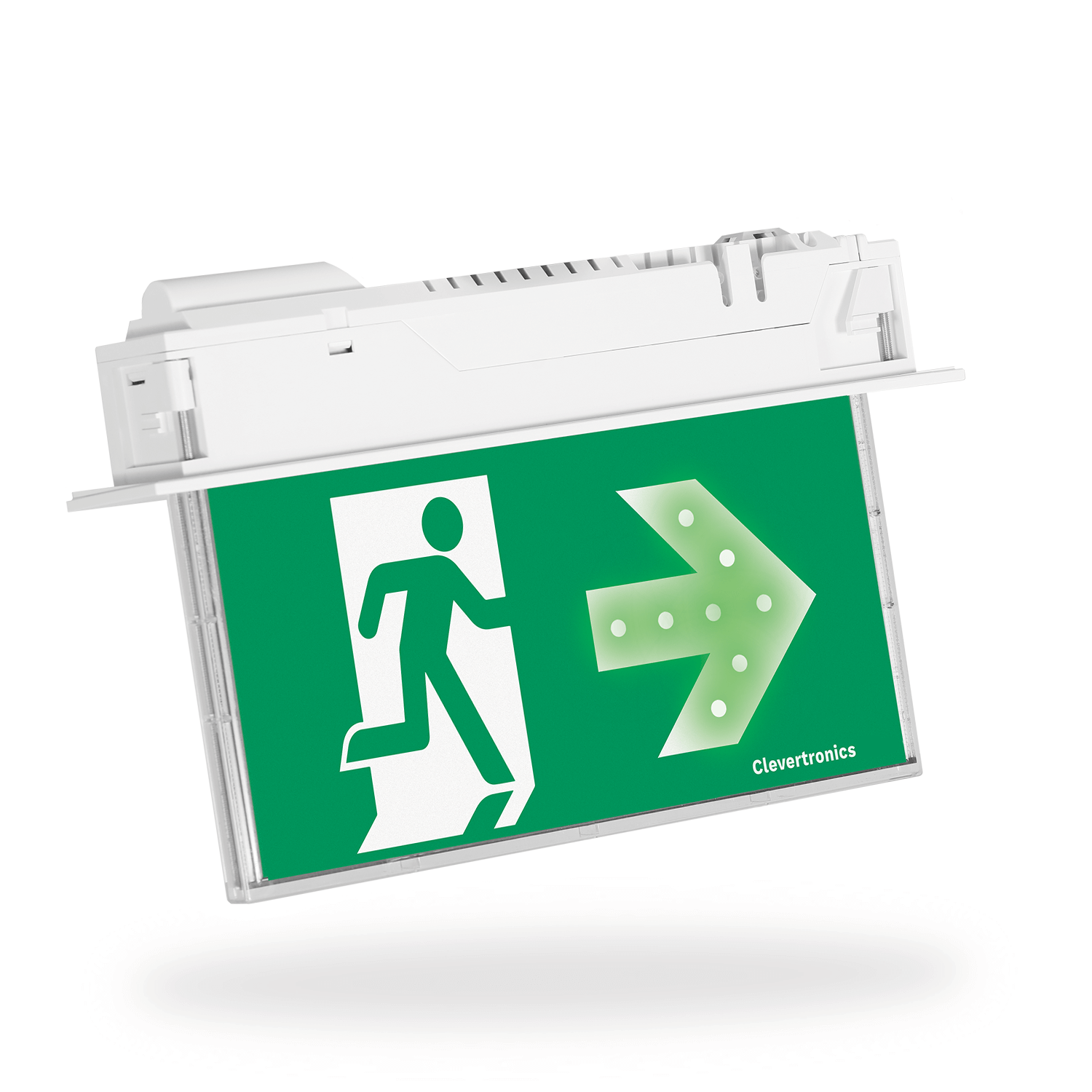

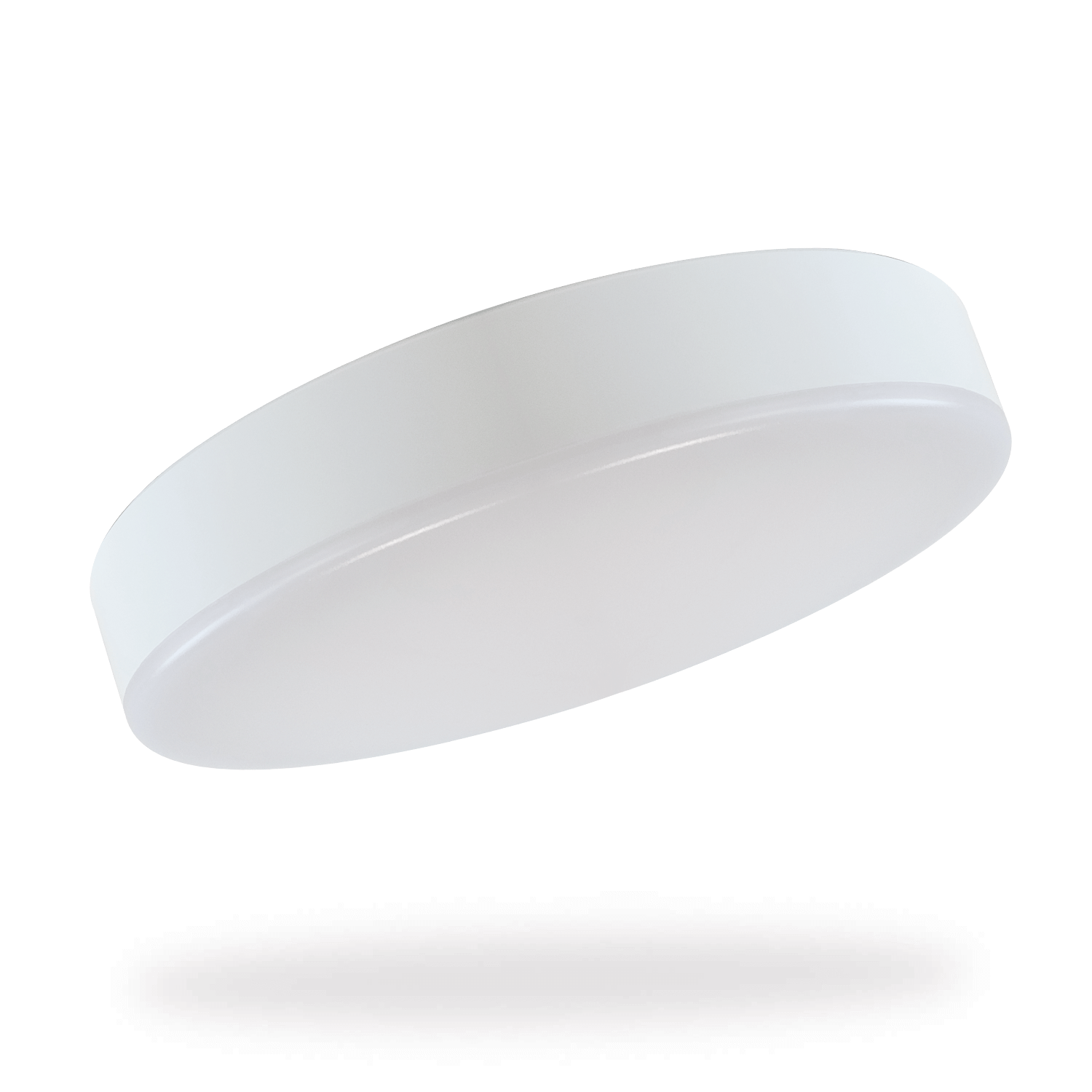

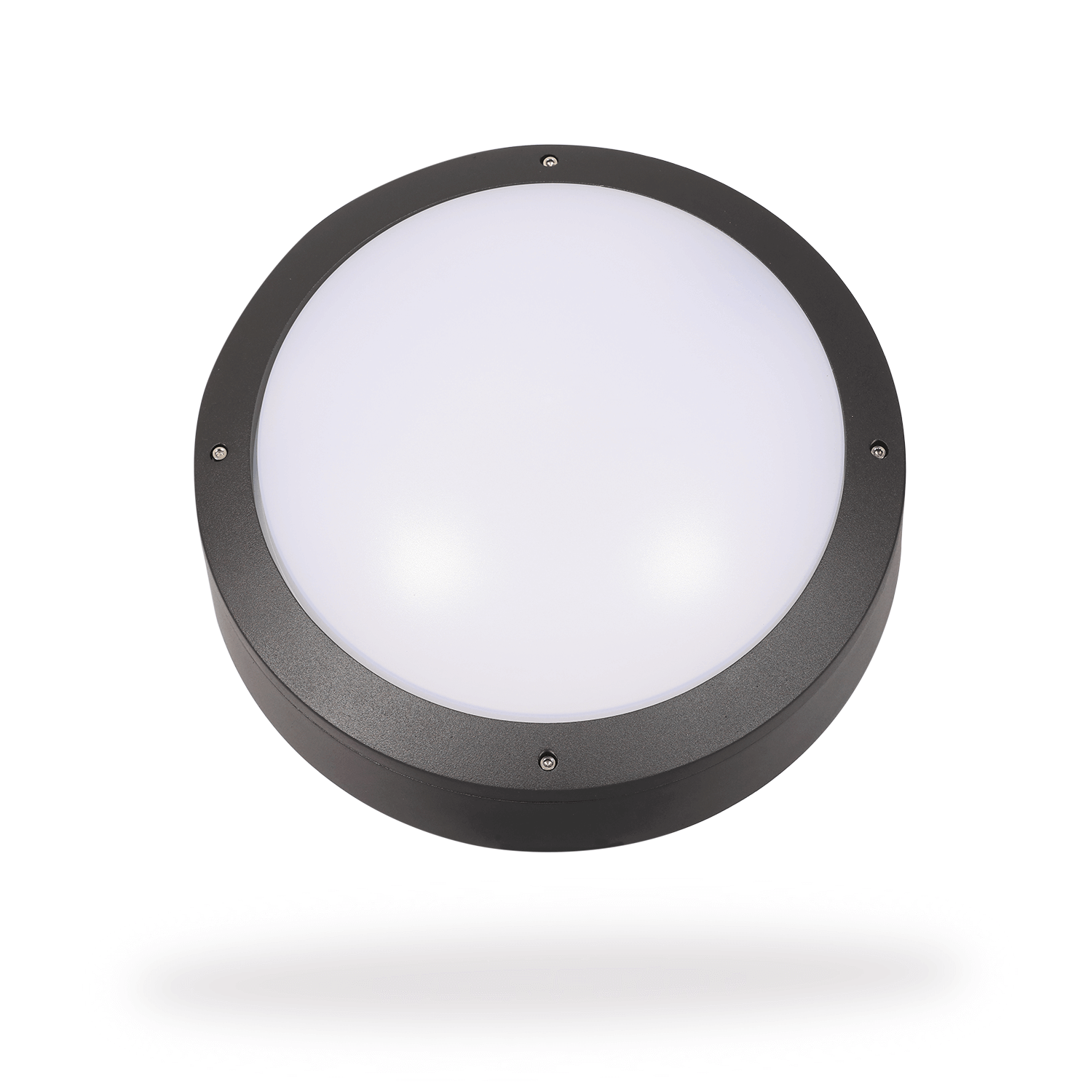

Clevertronics, along with two other emergency lighting companies placed a bid for the project, however, only Clevertronics was able to provide a comprehensive solution to meet all of the specifications, quality, installation and logistical challenges. The Clevertronics solution, proposed and accepted by Metro was based on the L10 Nanophosphate range, which met the required lighting and emergency lighting performance and also minimised the need for any large scale maintenance for at least a decade.

The trademark L10 Nanophosphate product features a world first: Lithium Iron Nanophosphate battery. The patented chemistry of L10 batteries are proven to provide three or four times the life of economy Nickel Cadmium or Nickel Metal Hydride batteries and 50% longer battery life compared to any other Lithium product on the market. Further, the light fittings were networked via the electrical power line, the existing telephone cable infrastructure and Metro Trains’ LAN/WAN ICT network in order to automatically perform and diagnose results from the six-monthly testing regime under the Australian standard AS2292.

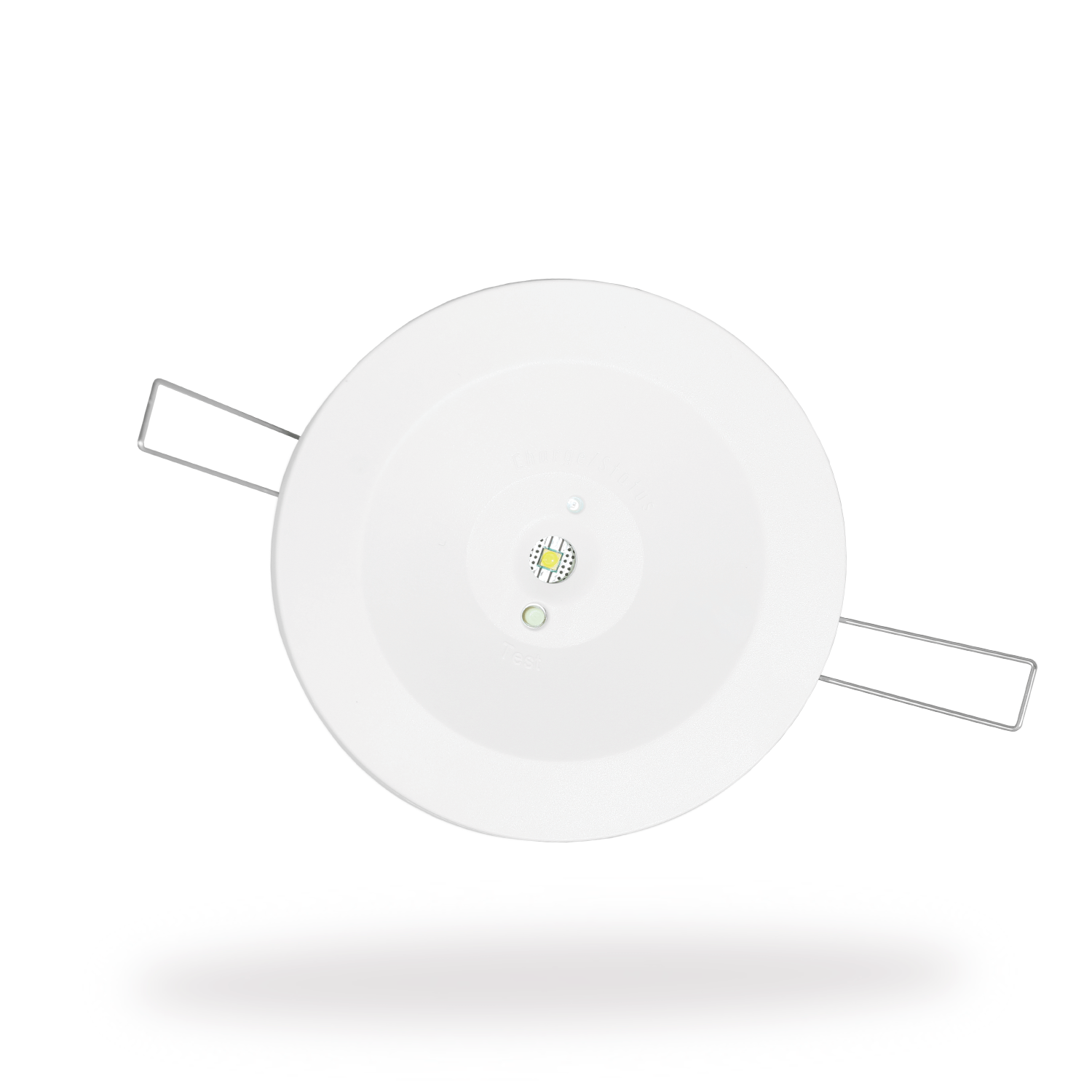

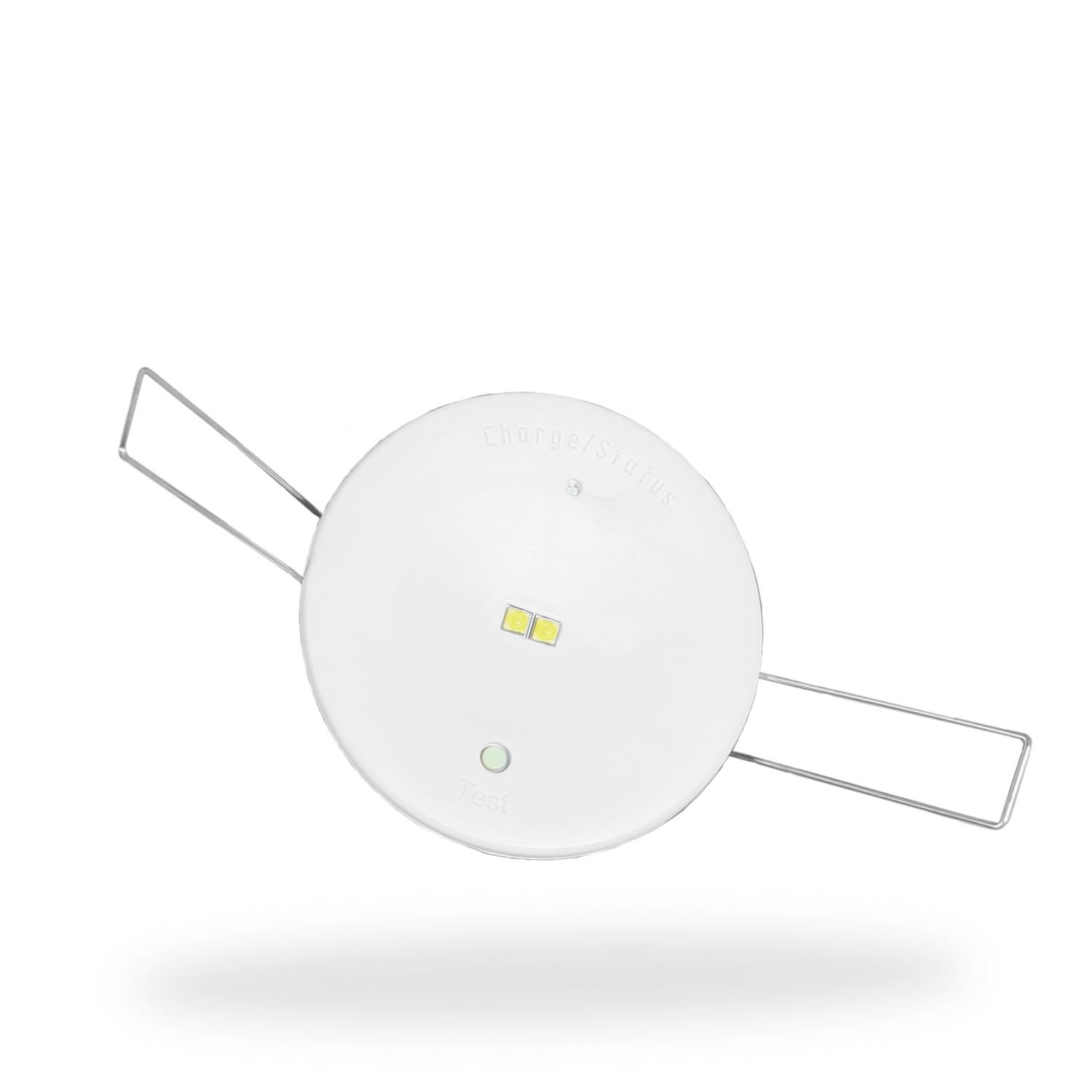

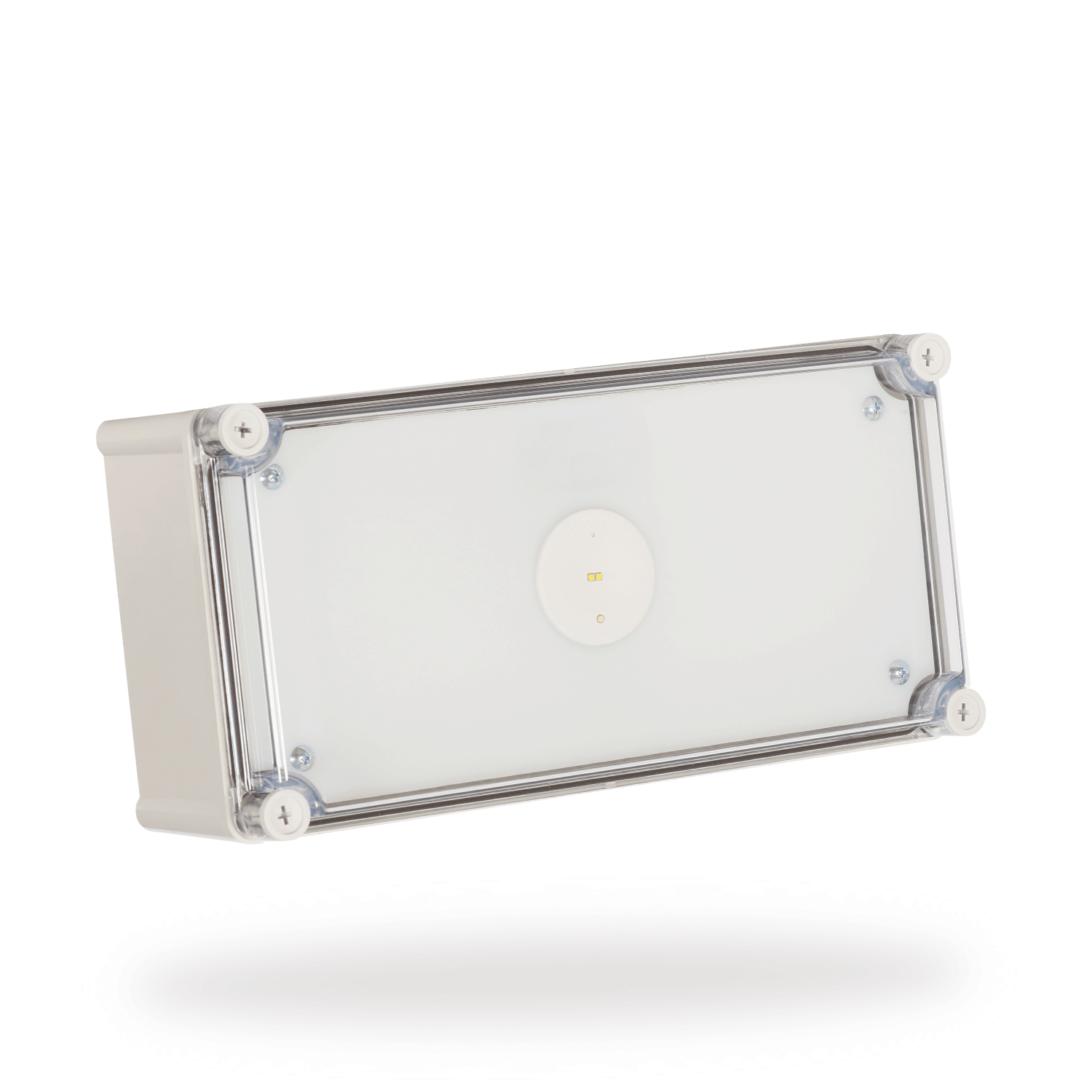

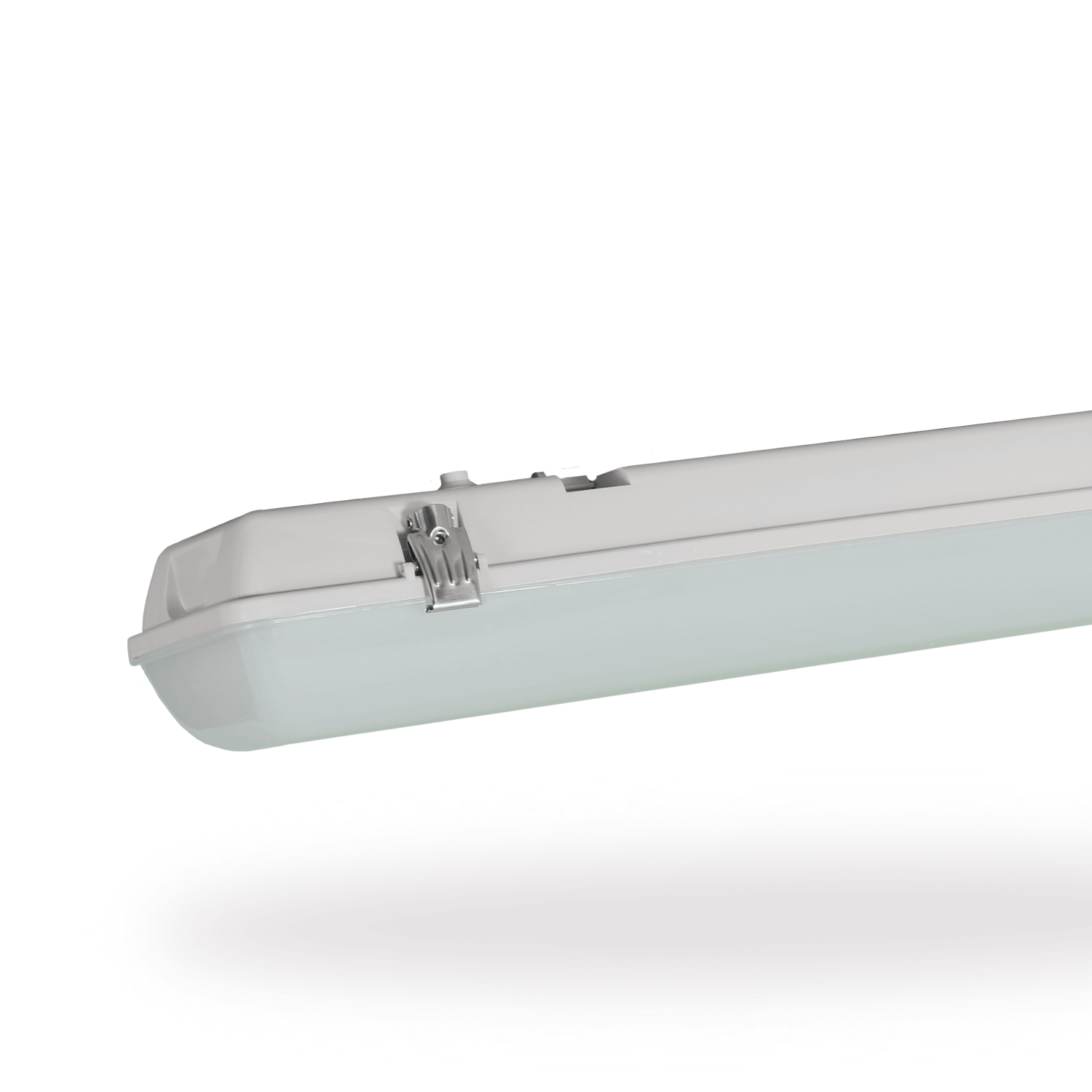

This was achieved with the Zoneworks XT monitored emergency lighting solution. Finally, the light source was comprised of the optically engineered weatherproof POD, two of which were fixed to an IP67 housing at various positions to induce vertically downward light. The housing was in turn fixed to a metal strut frame so that the complete unit would be easily installed and removed from the tunnel surface. The light source is provided via twin LEDs in each POD to meet the minimum amount of light in both normal lighting conditions and in emergency mode.

The Result - 100% of the fittings pass the test

Clevertronics engineers developed an initial set of 10 working prototypes for Metro to trial within two weeks of discussions about the specifications and required performance. These initial fittings were then tested on-site and some small mechanical modifications were made before the final fitting was ordered. The fittings were ordered in January 2015, and were supplied from March to June 2015.

A strict deadline had to be met to ensure Metro did not incur additional costs due to downtime in the tunnel networks. Once installed, the fittings were commissioned to the head end virtual server on the Metro ICT network.

At commissioning, all the fittings successfully communicated with the software to record 100% of the fittings pass the test with run times recorded to exceed 255 minutes (the software only measures run time to 255 minutes, however, it is likely the currently run times for these batteries under discharge conditions to be closer to 8 hours).