Reducing maintenence costs plus

improving testing and compliance

for Transport application

Background

RATP Dev operates and maintains urban and intercity transportation systems on four different continents.

They do so with the emphasis to make distances shorter to travel, boost local and regional economies and to bring people together. Their philosophy is to be ‘where you are’ and ‘where you want to go.’

Whilst doing routine evaluations across some of London's bus depots that they facilitate and run, the client was made aware that they were bordering compliance regulations and incurring high maintenance costs of their current emergency lighting system.

The Challenge

It became obvious that decision processes were being made by balancing three key elements:

- Regulatory compliance

- Initial cost base of system

- Ongoing maintenance costs.

However, budgets were a big consideration in the life safety system that was to be put forward. What was also made clear was to consider overall flexibility of the system, and future proof, any installation to progressively move to more innovative wireless systems as and when the time arose.

The Solution & Result

Working in partnership with RATP DEV and Powercor, we addressed each of the challenges individually and started to piece together the emergency lighting life safety system that would suit the customers specific needs.

To the right, you will see the life safety system put forward and approved for rollout across 12 of the London Bus Depots that RATP DEV manage and facilitate.

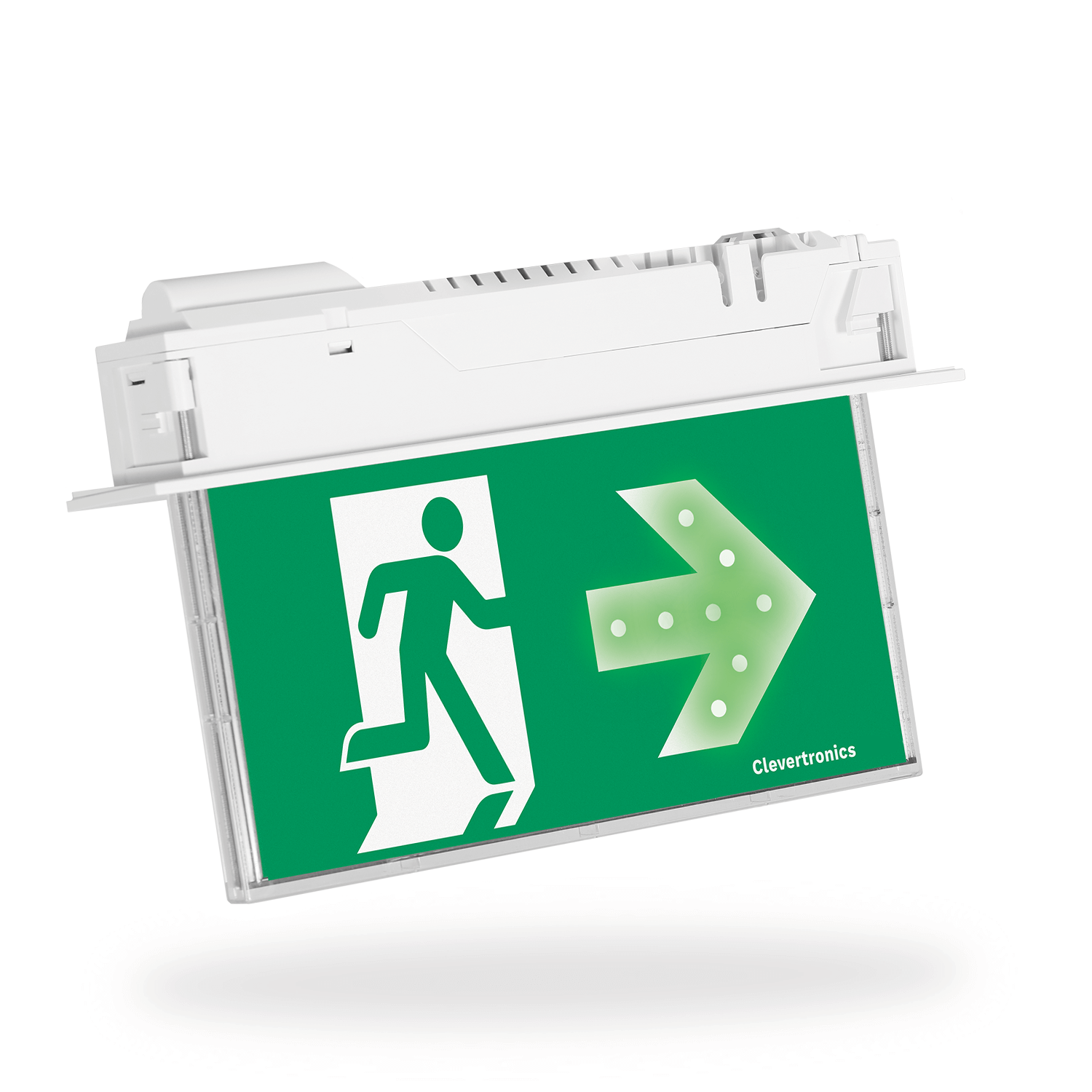

When choosing the perfect Fire Exit Sign, Ultrablade Pro Surface Mount Exit was chosen for its look and design to satisfy the architectural requirements for of each of the buildings. With a reduced reflection and halo effect on the diffuser and a decal that is scratch and fingerprint resistant it is the industry standard for an architectural blade exit sign.

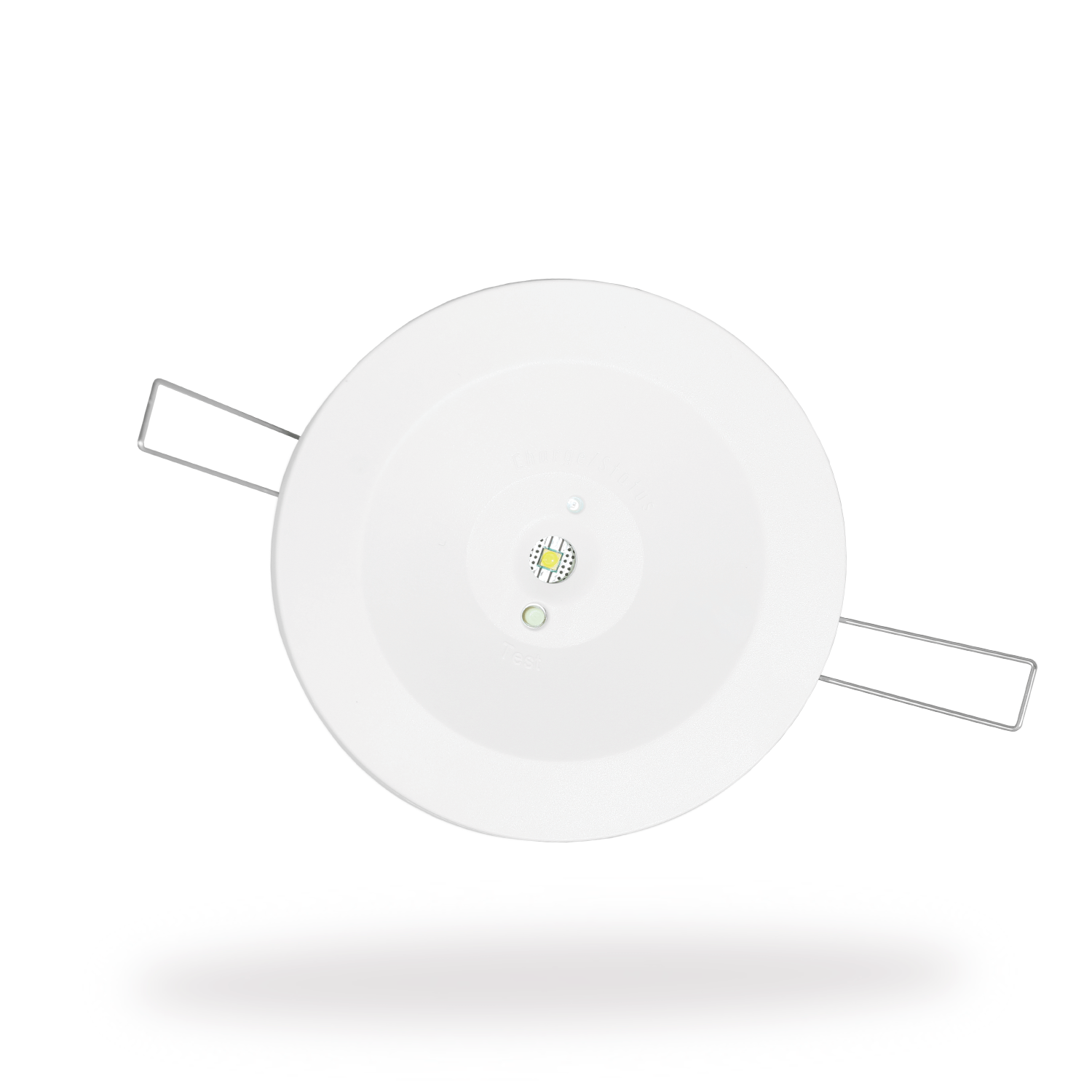

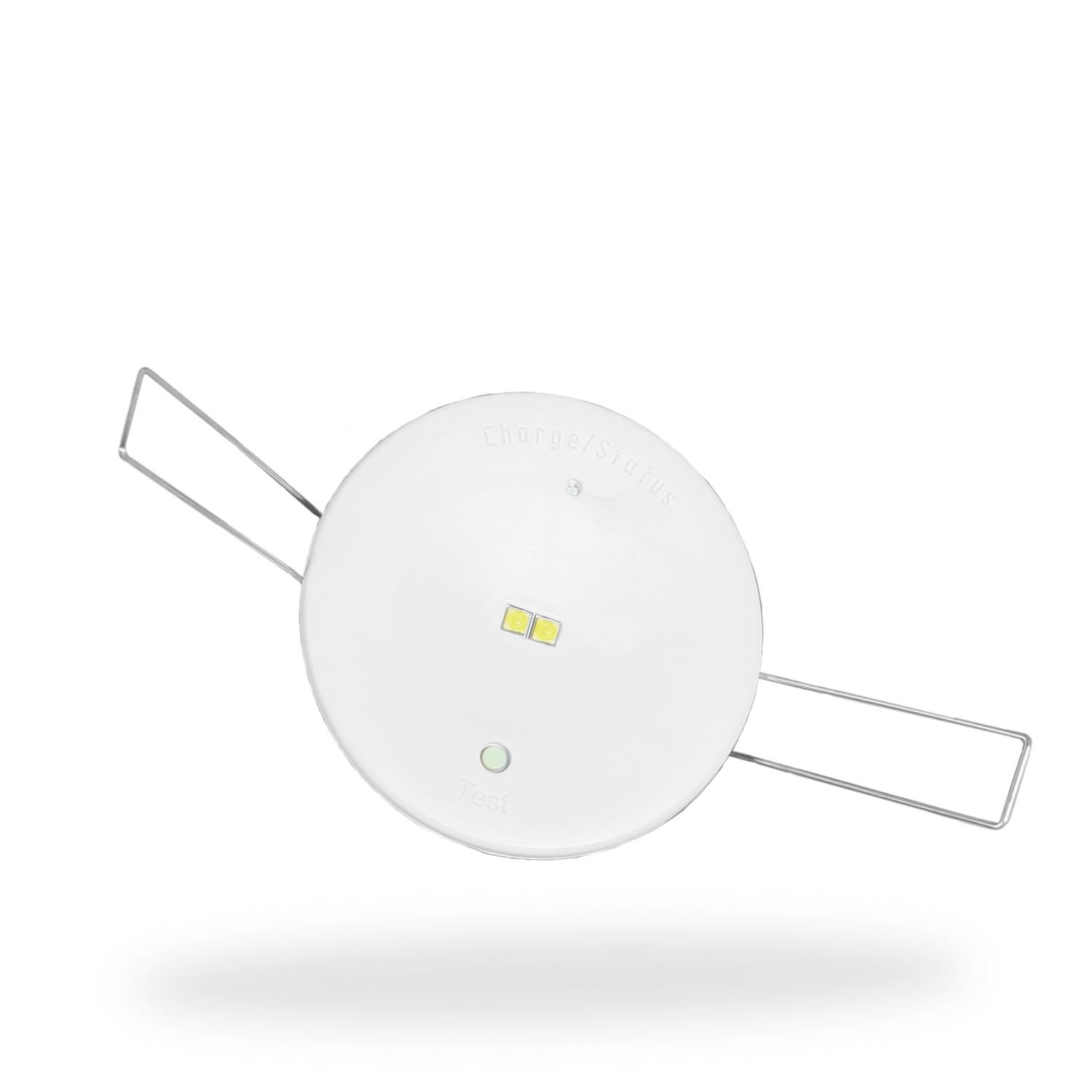

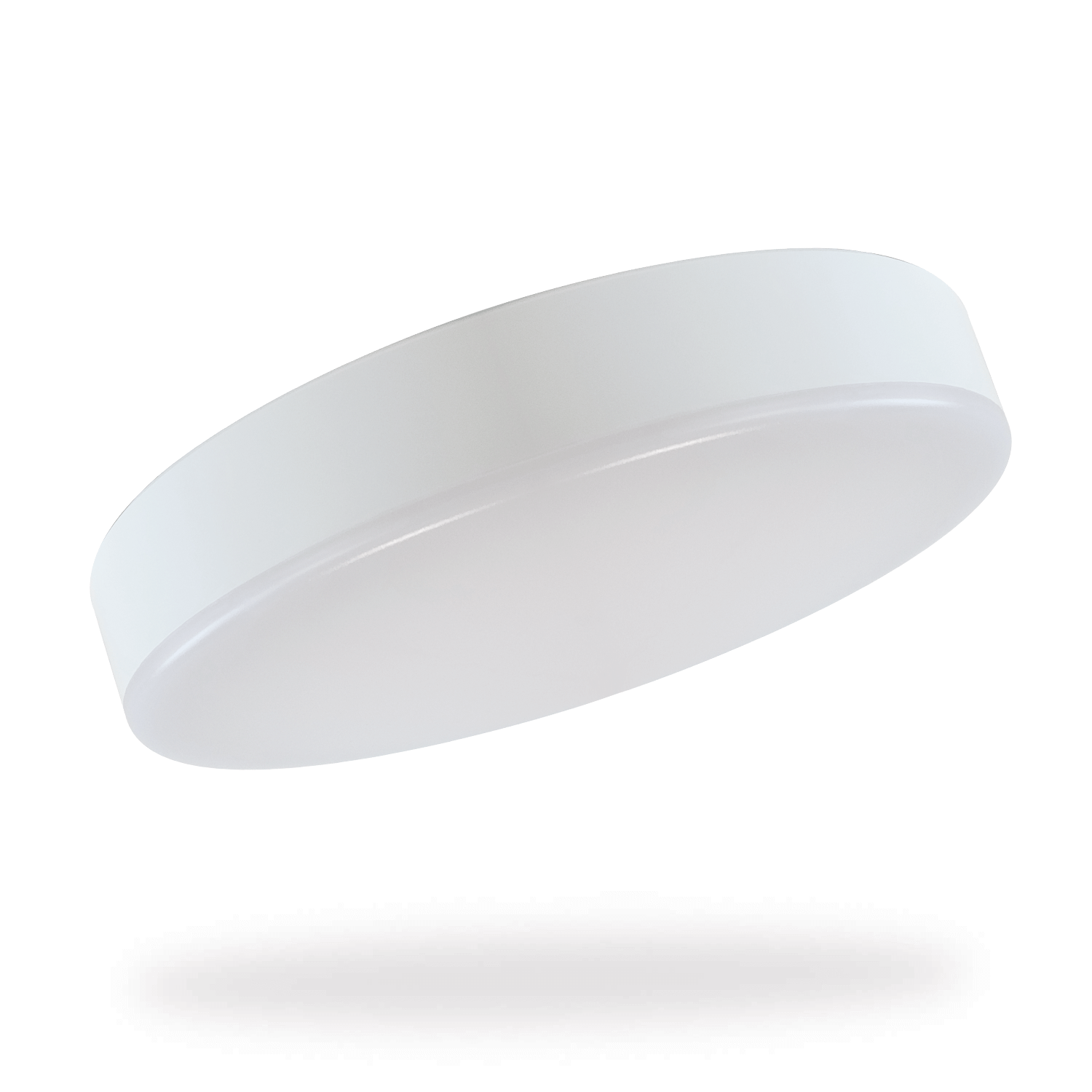

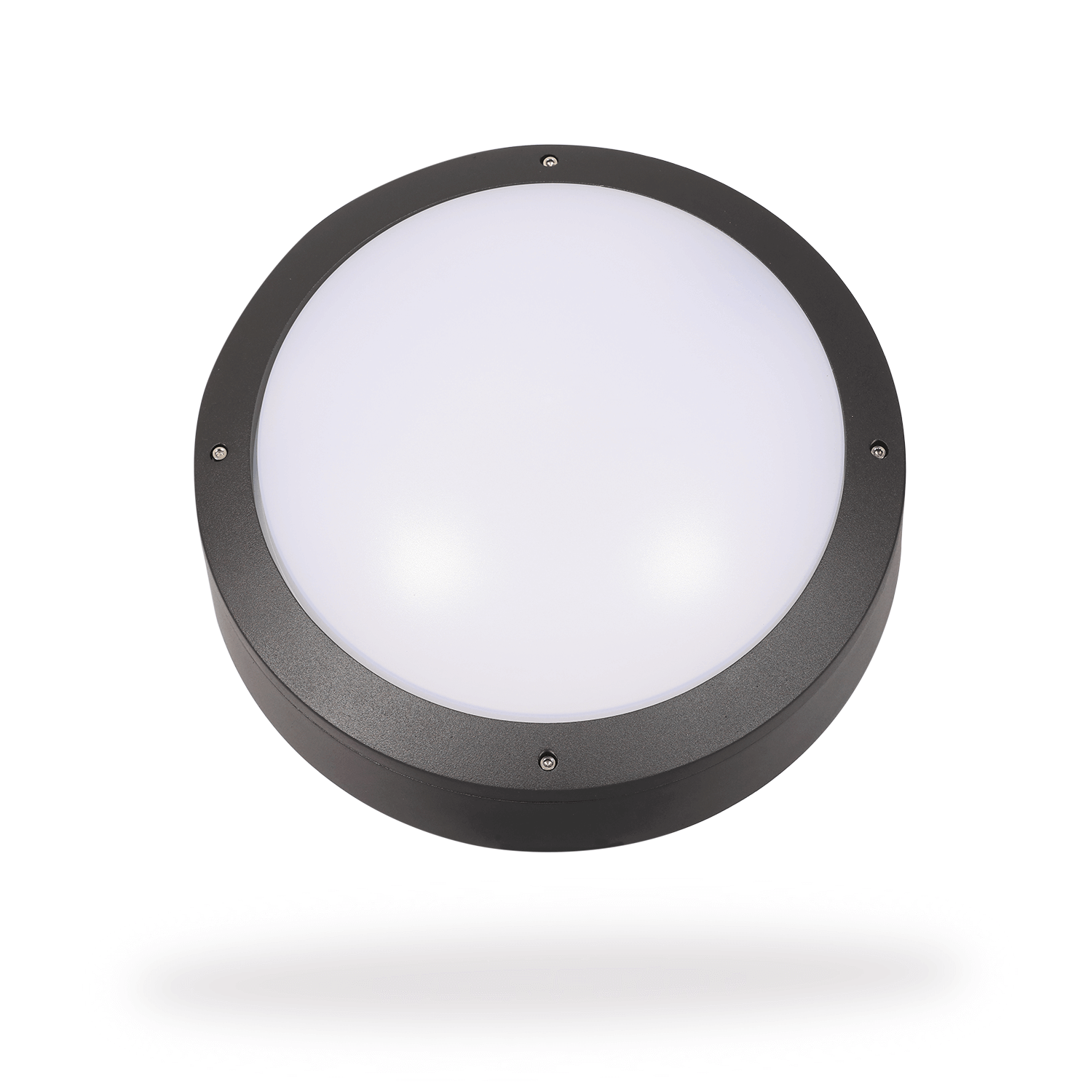

For spot illumination emergency lighting, Lifelight was specified which delivers lowest maintenance and energy costs and was the clear product of choice for this project supporting the initial cost base of the system.

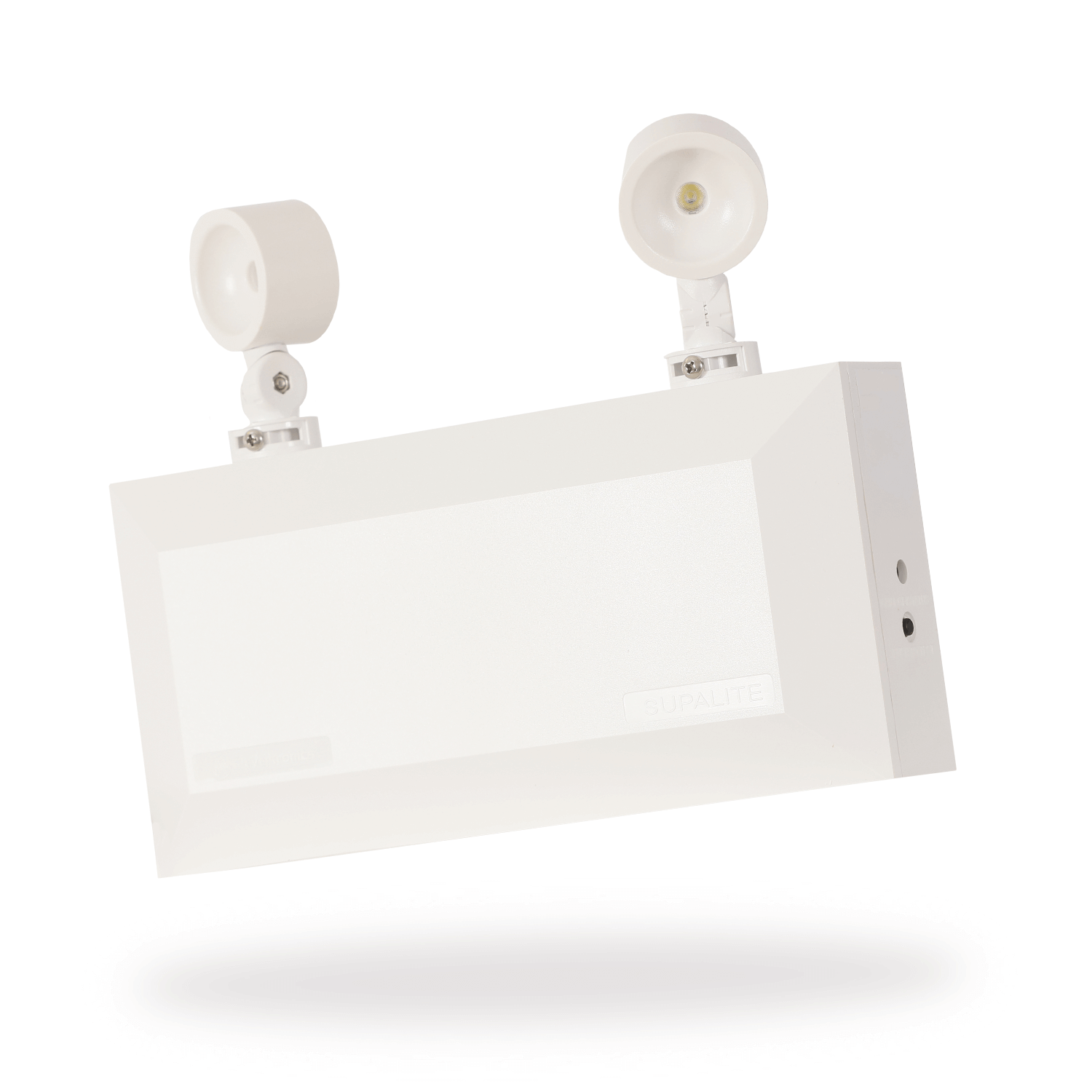

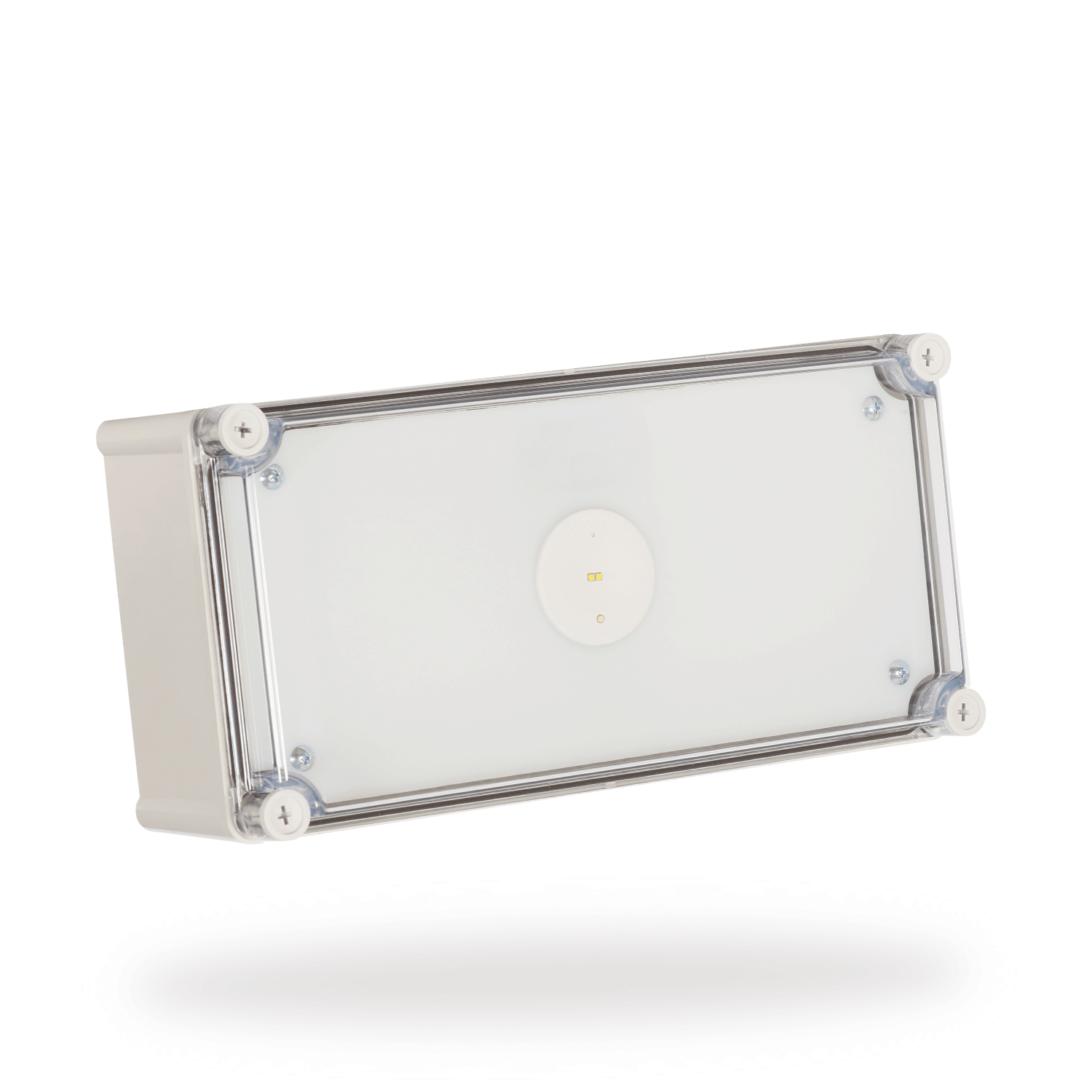

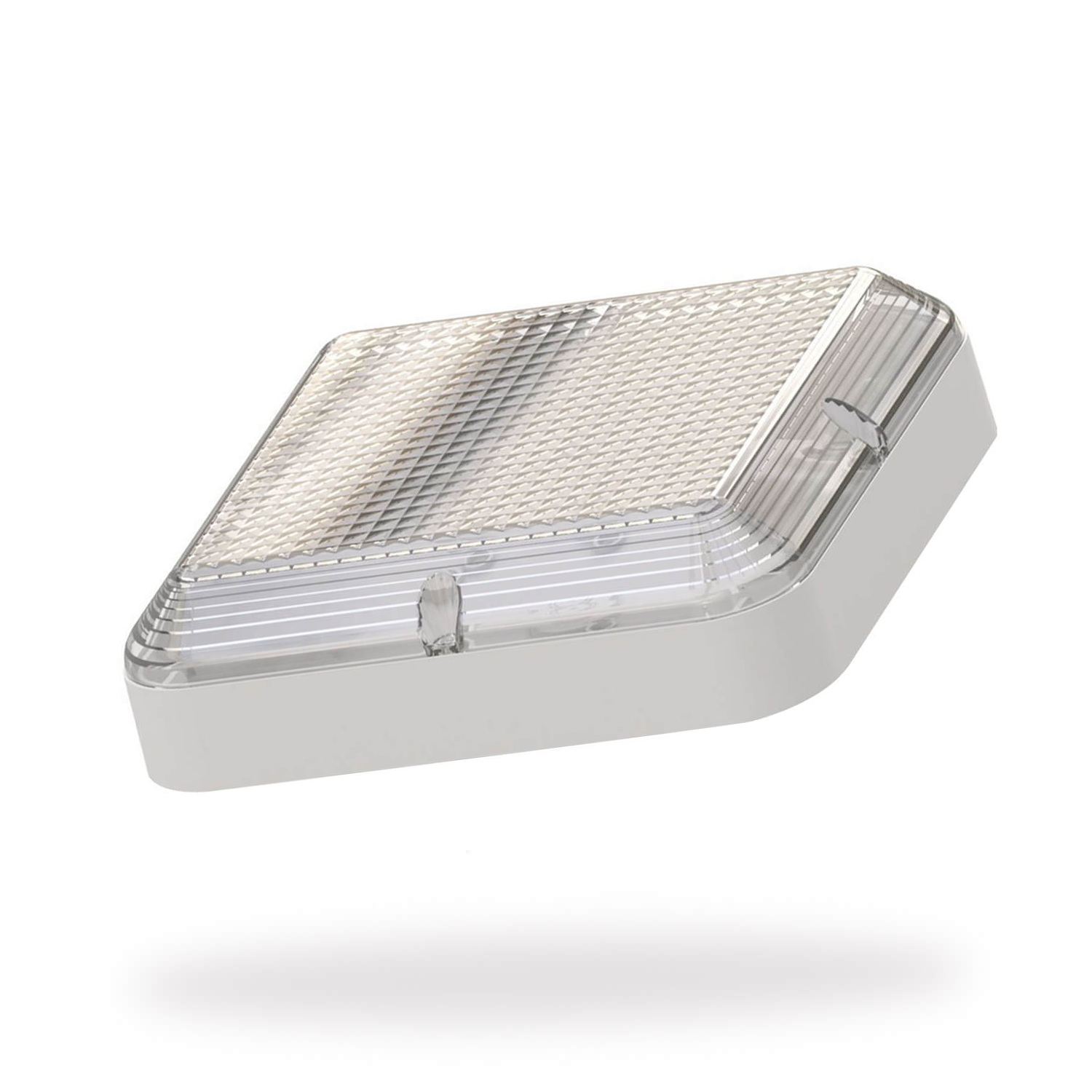

As for the main depot servicing areas, they needed a product with greater lumen outputs. The ARGO Weatherproof was the perfect choice for this application because if its its reliability, flexibility and good initial cost base. With an IP65 and IK08 impact ratings it comes combined with switchable colour and outputs.

When it came to solving the ongoing maintenance costs of the project, there was only one clear winner – CLP Lithium Iron Phosphate batteries. This product lasts three times longer than any other battery on the market and will deliver, on average, 50% total savings compared to others.

And the good news is, this system has been specified and futureproofed to be upgradeable to the ZoneWorks XT HIVE wireless system as and when the customer requires.

Overall, the team delivered a project that is easier to maintain and is fully compliant to BS EN 605982-22 and EN1838 and is ISO7010 enabling a safe environment for workers and passengers to experience.

Upgraded London Bus Depots

*Compared to standard battery technologies and based on 30ºC external ambient temperature, continuous operation.

"Choosing the right solution for this project was not very difficult as we instantly knew to meet maintenance reduction targets, continual compliance testing and reporting and upgradeability options for the future, Clevertronics were the clear choice"

Chris Wright

Powercor